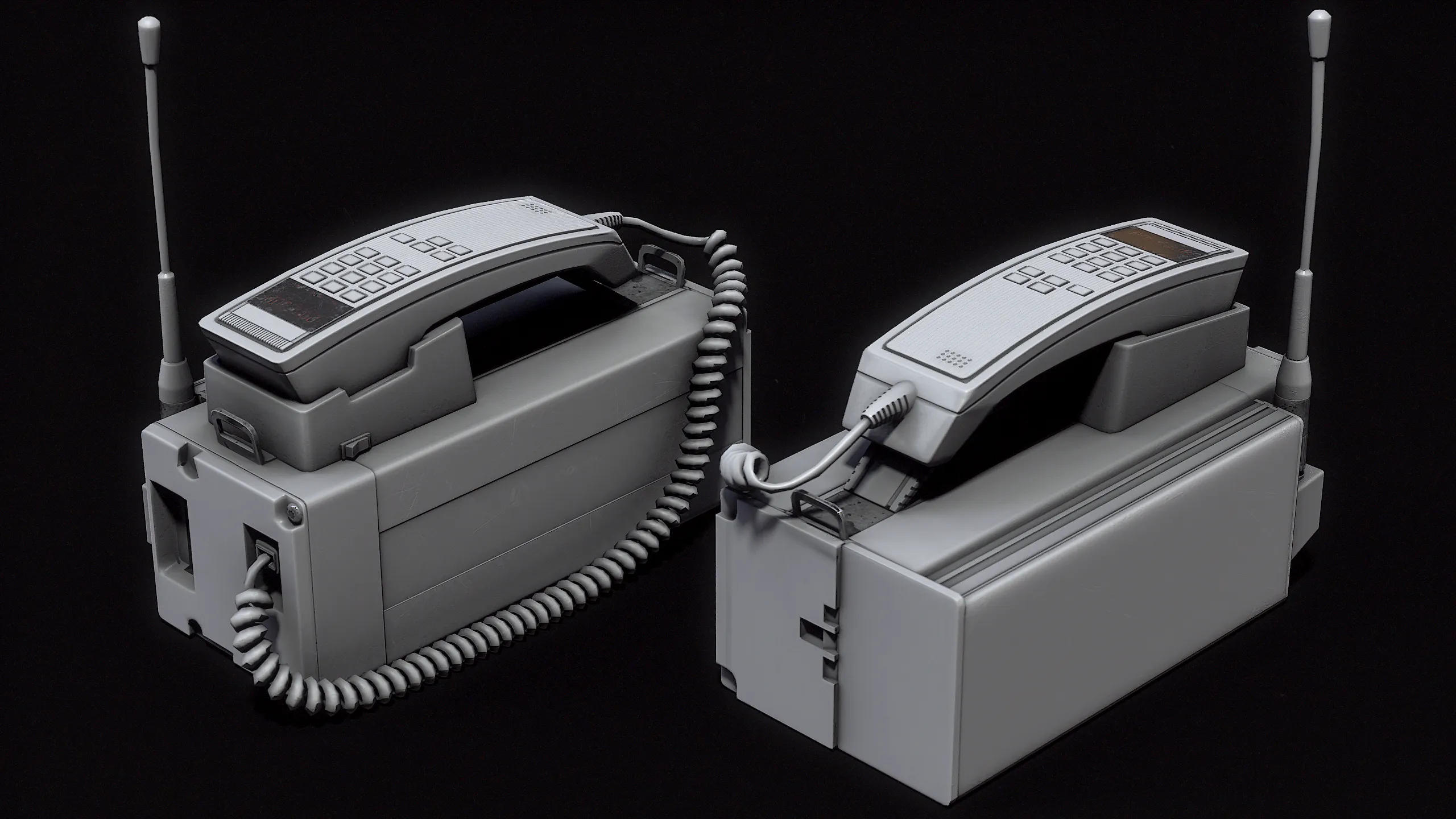

Motorola RAZR V3

Hard surface modeling study of the iconic Motorola RAZR V3 flip phone, focusing on precise mechanical details and material definition.

Project Overview

A detailed recreation of the iconic Motorola RAZR V3 flip phone, exploring hard surface modeling techniques and material definition for consumer electronics. This project focuses on capturing the precise mechanical details and premium feel that made this device a design icon of the mid-2000s.

Design Philosophy

The RAZR V3 represented a paradigm shift in mobile phone design—impossibly thin at 13.9mm, with a distinctive aluminum body and attention to premium materials. This recreation aims to capture that same precision and material quality through careful modeling and texturing.

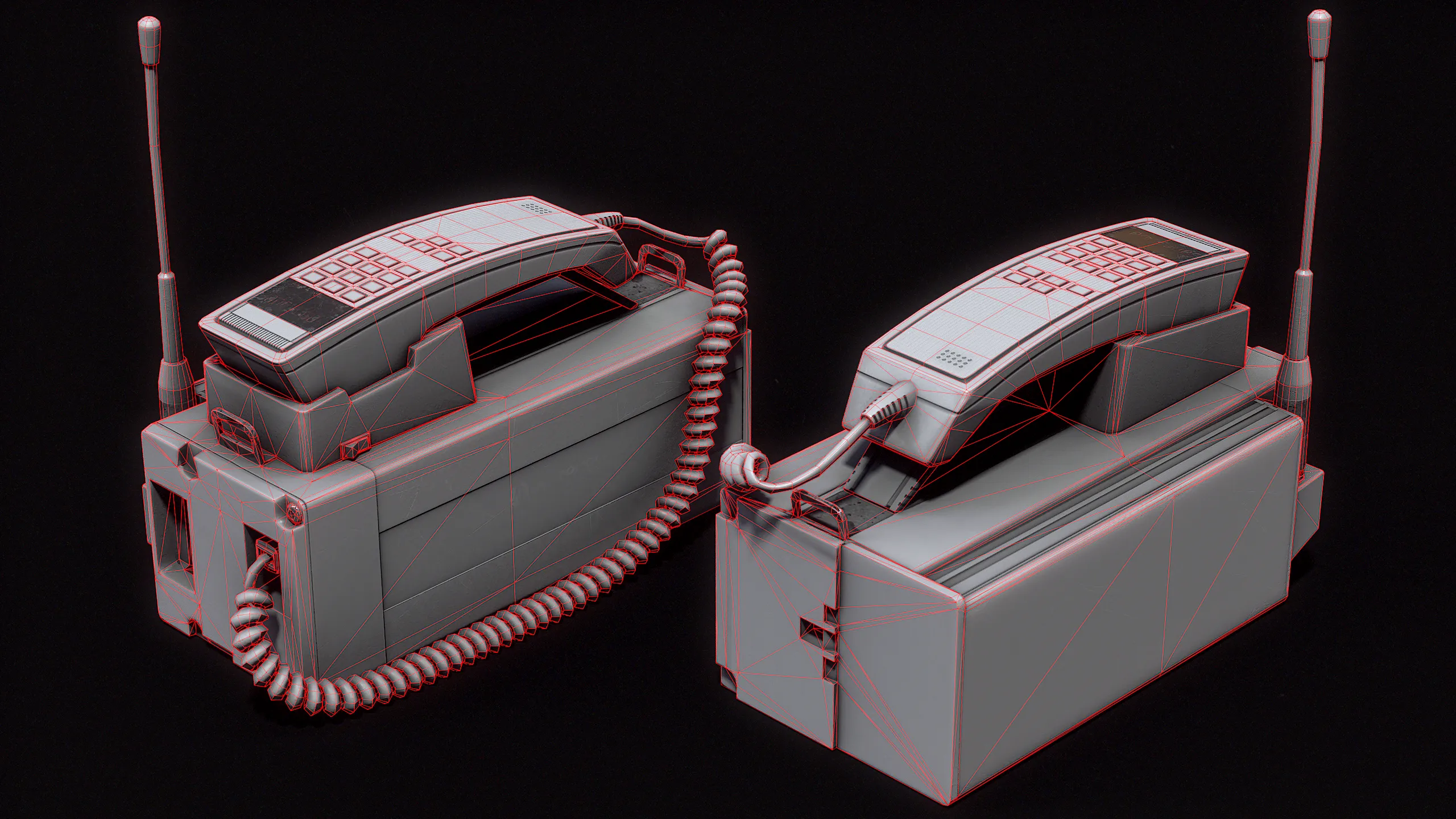

Modeling Approach

Precision Hard Surface

Technical modeling workflow emphasizing accuracy:

- Clean topology optimized for smooth surfaces and realistic reflections

- Precise mechanical details including button spacing, screen bezels, and seams

- Accurate hinge mechanism with proper articulation and assembly

- Careful edge flow to capture the signature brushed aluminum highlights

Technical Construction

The model breakdown includes:

- Modular assembly allowing for material variation and animation

- Mechanical tolerances between moving parts

- Surface detailing from macro forms to micro surface features

- UV layout optimized for texel density and baking efficiency

Material Development

PBR Texturing

Physically-based materials capture the device’s premium feel:

- Brushed aluminum finish with directional anisotropic highlights

- Glass materials for screen and camera lens with proper refraction

- Plastic keypads with subtle texture variation

- Rubber coatings on specific grip surfaces

Surface Details

Attention to subtle surface qualities:

- Fingerprint smudges and natural wear patterns

- Manufacturing marks like injection molding seams

- Screen display properties with realistic LCD characteristics

- Metallic variation across different surface treatments

Technical Execution

The model balances visual accuracy with practical real-time performance:

- Optimized polygon count suitable for product visualization

- High-quality normal maps capturing fine surface detail

- Material layering for realistic surface complexity

- Modular construction allowing for animation and configuration changes

Visual Presentation

Lighting and rendering setup emphasize the device’s premium materials:

- Studio lighting to showcase surface qualities

- Dramatic angles highlighting the thin profile

- Reflection control to bring out brushed aluminum direction

- Clean presentation focusing on form and material

Outcome

This project explores the intersection of technical precision and material authenticity in hard surface modeling, demonstrating workflows applicable to product visualization and realistic prop creation for real-time and offline rendering.

All modeling, texturing, and rendering by Carlos Garcia